Power Supply EMC Explained: EMI, EMS, Class B, and Key Considerations for Industrial Power Selection

As industrial automation, smart machinery, household appliances, and IoT devices continue to evolve, ensuring stable system performance in diverse electromagnetic environments has become increasingly important. Electromagnetic Compatibility (EMC) is a fundamental requirement that determines whether an electronic device can operate safely and reliably without creating or receiving unwanted electromagnetic interference.

This article provides a clear and structured overview of EMC fundamentals, including EMI and EMS classifications, key test items, noise coupling mechanisms, the difference between Class A and Class B emission limits, and why the power supply plays a central role in overall EMC performance. It also outlines essential design considerations and how ARCH supports system-level EMC compliance through power design experience.

What Is EMC and Why Does It Matter?

EMC describes a device’s ability to operate properly in its intended electromagnetic environment while fulfilling two key conditions:

- Not disturbing other equipment (EMI – Electromagnetic Interference)

Electronic devices generate high-frequency switching noise, loop currents, and transient signals. If not controlled properly, these disturbances may affect nearby controllers, sensors, communication modules, displays, or other electronic systems. - Withstanding disturbances from external sources (EMS – Electromagnetic Susceptibility)

Electrical environments often include static discharge, surge events, relay switching transients, and radio-frequency noise. A device must be able to resist these disturbances to maintain continuous operation.

In industrial automation and household applications—where systems are densely integrated—reliable EMC performance is directly tied to operational stability and product safety.

EMI and EMS Test Requirements

Before entering the market, most industrial and consumer devices must undergo a full EMC assessment. EMC evaluations are generally divided into two categories:

- EMI Tests – Limiting Noise Emitted by the Device

- CE (Conducted Emission)

Measures noise conducted through AC/DC power lines. - RE (Radiated Emission)

Measures electromagnetic energy radiated through air.

Excessive EMI may interfere with control systems, communication interfaces, wireless modules, and other sensitive devices.

- CE (Conducted Emission)

- EMS Tests – Ensuring Immunity to External Disturbances

Common industry-required immunity tests include:

Test Item Simulated Condition ESD (Electrostatic Discharge) Human contact, casing discharge EFT (Electrical Fast Transient) Relay/motor switching transients Surge Immunity Lightning-induced surge, grid fluctuation RS / CS (RF Immunity) Radio, mobile, and electromagnetic field interference Poor EMS performance can lead to:

unexpected resets, communication faults, display flicker, unstable behavior, or even system shutdown.

Noise Coupling Mechanisms: How Interference Enters a System

Electromagnetic noise reaches sensitive circuits through different coupling paths. Understanding these mechanisms is crucial for effective EMC design.

- Conducted Coupling

Noise enters through power or signal lines. - Capacitive Coupling

High dv/dt switching or closely routed traces induce unintended coupling. - Inductive Coupling

High current loops, motors, or relays generate magnetic fields that affect nearby circuitry. - Radiated Coupling

Noise propagates through air as electromagnetic waves.

Mitigating these coupling paths in early design stages significantly improves EMC performance.

Class A vs. Class B: Understanding Emission Limits

EMI emission limits are typically classified into:

| Category | Application | Restrictiveness |

| Class A | Industrial, heavy-duty environments | Less strict |

| Class B | Residential, commercial, light industrial | Most strict |

Although industrial systems operate in Class A environments, Class B power supplies are often preferred, especially when devices include:

- human-machine interfaces

- communication modules

- displays or touch panels

- installation in semi-indoor or mixed environments

Stricter emission limits help reduce system interference and simplify overall EMC compliance.

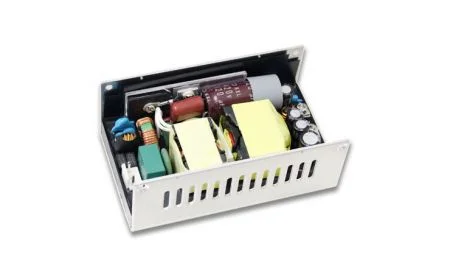

Why the Power Supply Is Central to EMC Performance

In practical EMC debugging, a high percentage of failures are directly related to the power supply.

This is due to several inherent characteristics:

- Switching operation inherently generates high-frequency noise

MOSFET switching, rectification loops, and magnetic components all contribute to EMI. - The power supply is the primary interface for external disturbances

Surge, EFT, and ESD events typically enter the system through the power stage. - System grounding and wiring are concentrated around the power supply

Incorrect routing, discontinuous ground planes, or poor filter placement can greatly amplify EMI issues. - Increasing miniaturization raises EMC complexity

Compact IoT devices, home appliances, and industrial modules often place antennas and power circuits in close proximity.

Selecting a well-designed power supply with strong EMI/EMS characteristics is one of the most effective ways to improve system-level EMC.

Key EMC Design Principles

Regardless of the application, the following principles are widely applicable:

- Place EMI filters as close to the AC input as possible

- Separate high-voltage and low-voltage routing

- Minimize switching loop areas

- Avoid coiled or bundled wires forming loops

- Maintain continuous and well-connected ground planes

- Use shielding for sensitive circuits or RF zones when needed

Applying these principles early in the design process significantly improves EMC robustness and reduces certification risk.

How ARCH Helps Enhance EMC Performance in Electronic Systems

ARCH has extensive experience in industrial control, home appliances, smart devices, communications, and other application fields. Over the years, we have built strong expertise in power supply EMC design, system integration, and practical verification. Our goal is to help customers improve both EMI and EMS performance at the system level, making it easier for products to pass certification and maintain long-term stability in real-world environments.

ARCH’s support includes:

- Power architectures with enhanced EMI/EMS performance

Through optimized filtering, switching control, and protection mechanisms, ARCH power supplies reduce emitted noise and strengthen immunity to surge, ESD, and fast transient disturbances. - Design recommendations for system wiring, filtering, and grounding

We provide practical routing and layout guidance during the early design stages, helping customers reduce EMI root causes and improve overall EMC compliance. - Support for diverse application environments and global EMC standards

Whether for industrial equipment, home appliances, smart displays, energy systems, or IoT devices, ARCH can assist customers in selecting power solutions that meet specific environmental and regulatory requirements. - EMC testing and troubleshooting assistance

When customers encounter EMI/EMS issues during testing, ARCH offers directional improvement suggestions to accelerate debugging and shorten time-to-market.

Through proper power supply selection and comprehensive EMC planning, products can maintain stability, safety, and competitiveness across diverse operating environments. Moving forward, ARCH will continue to share insights on power supply applications and EMC technologies, supporting customers in achieving better outcomes throughout their product development process.

Explore More ARCH AC-DC Power Solutions

Contact Us

- Related Products

Power Supply EMC Explained: EMI, EMS, Class B, and Key Considerations for Industrial Power Selection | ARCH

The ARCH power supply blog shares practical guides on AC/DC design, EMC, safety approvals and thermal performance for real-world industrial and medical projects.

Each article is written for hardware engineers, project managers and buyers who need clear, vendor-backed explanations rather than generic theory.

Browse our latest posts to compare architectures, avoid common design mistakes and make more confident sourcing decisions for your next power platform.

Our Company Facts in Numbers

0

Years of Experience

0

Global Customers

0

Countries

0%

R&D Staff